Underwater oil rigs are vital components of the global energy infrastructure, and understanding the role of uap underwater oil rig is essential for ensuring safe and efficient operations. These massive structures operate in some of the harshest environments on Earth, where steam plays a crucial role in various processes. As the demand for energy continues to grow, the importance of optimizing these operations cannot be overstated.

Oil extraction from beneath the ocean floor involves complex engineering solutions, and steam is one of the critical elements used in this process. Whether it's for heating, power generation, or maintaining the integrity of equipment, steam systems on underwater oil rigs are designed to withstand extreme conditions. This article delves into the intricacies of uap underwater oil rig steam and its applications.

From the technical aspects of steam generation to safety protocols and environmental considerations, this guide aims to provide a comprehensive overview of the subject. Whether you're an industry professional, a student, or simply curious about the inner workings of offshore oil operations, this article will serve as a valuable resource.

Read also:Myers And Smith The Ultimate Guide To Their Legacy Contributions And Impact

Table of Contents

- Introduction to Underwater Oil Rig Steam

- The History of Underwater Oil Rig Operations

- Understanding Steam Systems on Oil Rigs

- Applications of UAP Underwater Oil Rig Steam

- Safety Protocols for Steam Operations

- Environmental Considerations

- Maintenance and Optimization

- Innovations in Steam Technology

- Regulations and Compliance

- The Future of Underwater Oil Rig Steam

Introduction to Underwater Oil Rig Steam

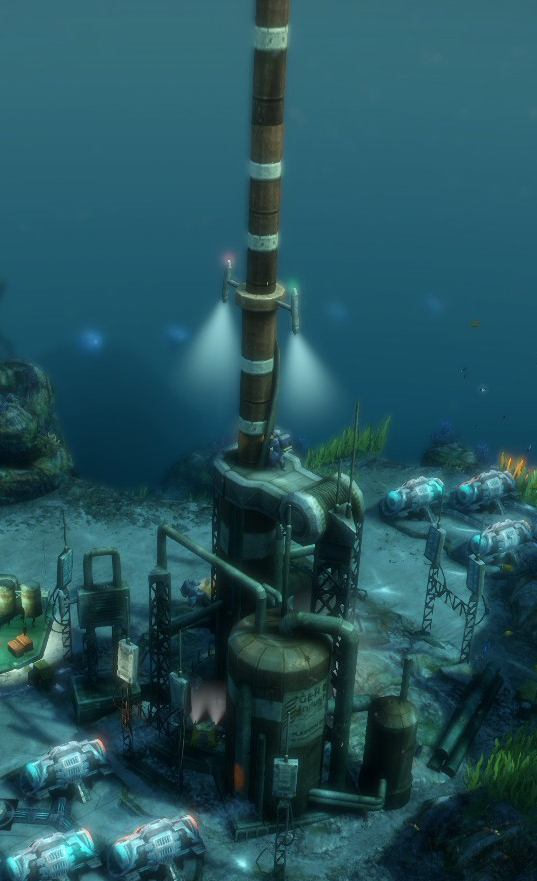

UAP underwater oil rig steam is a critical component in the operation of offshore drilling platforms. These rigs rely on steam for a variety of purposes, including heating, power generation, and equipment maintenance. The steam systems used in these environments are specifically designed to withstand the unique challenges posed by underwater conditions, such as high pressure and corrosive seawater.

Why Steam is Essential

Steam plays a vital role in the efficiency and safety of underwater oil rig operations. It is used to:

- Heat crude oil to facilitate extraction and transportation

- Generate electricity for onboard systems

- Maintain the temperature of pipelines to prevent wax buildup

- Provide power for essential equipment and machinery

The History of Underwater Oil Rig Operations

The development of underwater oil rigs has been a gradual process, with significant advancements occurring over the past century. The use of steam in these operations dates back to the early days of offshore drilling, when engineers first realized the potential of steam power in harsh marine environments.

Key Milestones

Some of the key milestones in the history of underwater oil rig operations include:

- The first offshore drilling platform was built in 1897

- Advancements in steam technology during the 20th century

- The introduction of modern steam systems in the 1980s

Understanding Steam Systems on Oil Rigs

Steam systems on underwater oil rigs are complex and highly engineered. They consist of boilers, turbines, and heat exchangers, all of which work together to generate and distribute steam throughout the rig. These systems are designed to operate efficiently while minimizing environmental impact.

Components of a Steam System

The main components of a steam system include:

Read also:Catch A Cab The Ultimate Guide To Efficient And Hasslefree Transportation

- Boilers: Used to generate steam by heating water

- Turbines: Convert steam energy into mechanical power

- Heat Exchangers: Transfer heat between fluids

Applications of UAP Underwater Oil Rig Steam

The applications of uap underwater oil rig steam are diverse and essential to the operation of offshore platforms. Some of the most common applications include:

Heating and Power Generation

Steam is used to heat crude oil, which helps to reduce viscosity and improve flow. It is also used to generate electricity for onboard systems, ensuring that the rig remains operational even in remote locations.

Safety Protocols for Steam Operations

Safety is a top priority in the operation of underwater oil rigs, and steam systems are no exception. Rigorous safety protocols are in place to ensure the safe operation of these systems, including regular inspections, maintenance schedules, and emergency response plans.

Common Safety Measures

Some of the common safety measures include:

- Regular inspections of boilers and turbines

- Training programs for rig personnel

- Implementation of emergency shutdown procedures

Environmental Considerations

The environmental impact of uap underwater oil rig steam operations is a growing concern. Efforts are being made to reduce the carbon footprint of these operations and minimize the impact on marine ecosystems. Innovations in steam technology are helping to achieve these goals.

Reducing Environmental Impact

Strategies for reducing the environmental impact include:

- Using renewable energy sources to power steam systems

- Implementing advanced water treatment processes

- Adopting best practices for waste management

Maintenance and Optimization

Maintenance is critical to the efficient operation of steam systems on underwater oil rigs. Regular maintenance ensures that these systems remain in good working order, reducing the risk of breakdowns and improving overall efficiency.

Optimizing Steam Systems

Some strategies for optimizing steam systems include:

- Upgrading to more efficient boilers and turbines

- Implementing predictive maintenance technologies

- Monitoring system performance in real-time

Innovations in Steam Technology

Innovations in steam technology are driving improvements in the efficiency and sustainability of underwater oil rig operations. From advanced materials to smart monitoring systems, these innovations are helping to transform the industry.

Emerging Technologies

Some of the emerging technologies include:

- Hybrid steam systems that combine traditional and renewable energy sources

- Smart sensors for real-time monitoring of steam systems

- Advanced materials for improved durability and efficiency

Regulations and Compliance

The operation of underwater oil rigs is subject to strict regulations and compliance requirements. These regulations cover a wide range of areas, including safety, environmental protection, and worker health. Compliance with these regulations is essential for the continued operation of these facilities.

Key Regulations

Some of the key regulations include:

- International Maritime Organization (IMO) guidelines

- Occupational Safety and Health Administration (OSHA) standards

- Environmental Protection Agency (EPA) regulations

The Future of Underwater Oil Rig Steam

The future of uap underwater oil rig steam looks promising, with continued advancements in technology and increasing focus on sustainability. As the industry evolves, the role of steam in offshore operations is likely to become even more important.

Trends to Watch

Some of the trends to watch include:

- Growing adoption of renewable energy sources

- Increased use of artificial intelligence and machine learning

- Development of new materials and technologies

Conclusion

In conclusion, uap underwater oil rig steam plays a critical role in the operation of offshore drilling platforms. From heating and power generation to safety protocols and environmental considerations, steam systems are essential to the efficiency and sustainability of these operations. As the industry continues to evolve, innovations in steam technology will play a key role in shaping the future of underwater oil rig operations.

We invite you to share your thoughts and experiences in the comments section below. Additionally, feel free to explore other articles on our site for more insights into the world of energy and engineering. Together, we can continue to learn and grow in our understanding of this vital field.